Are you curious to know what is electroforming? You have come to the right place as I am going to tell you everything about electroforming in a very simple explanation. Without further discussion let’s begin to know what is electroforming?

What Is Electroforming?

Electroforming, a fascinating process in metallurgy and manufacturing, represents a unique and intricate method of depositing metal onto a conductive surface through an electrochemical reaction. This technique has found diverse applications across various industries, from jewelry-making to advanced technological fields, due to its precision, versatility, and ability to create intricate and detailed metal structures.

The Electroforming Process

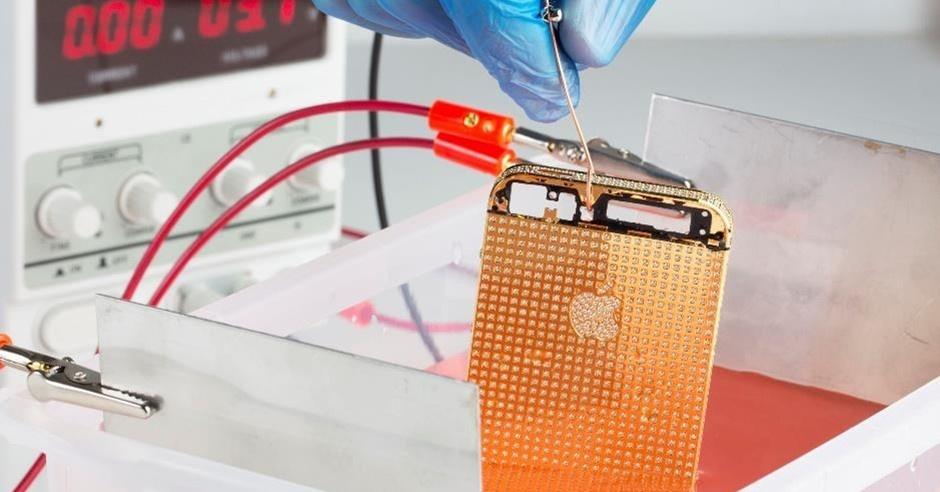

- Principle of Electrodeposition: Electroforming involves the controlled deposition of metal ions onto a conductive surface, typically a mold or substrate, through an electrolytic bath. This bath contains a solution of metal salts and functions as the medium for the electrochemical reaction.

- Electric Current and Metal Deposition: A direct electric current passes through the electrolytic solution, causing the metal ions to dissolve from the anode and plate onto the cathode (the conductive surface), forming a layer of metal with precise thickness and shape.

Applications In Different Industries

- Jewelry Making: In the jewelry industry, electroforming allows artisans to create intricate and lightweight metal jewelry pieces with detailed designs, textures, and patterns that would be challenging to achieve through traditional methods.

- Microfabrication and Microengineering: In advanced technological fields, electroforming is used in microfabrication processes to create microstructures, micro-components, and devices with high precision, such as microelectromechanical systems (MEMS) and microfluidic devices.

- Prototyping and Manufacturing: It’s also utilized in prototyping and manufacturing industries to create molds, prototypes, and components with intricate details, offering a cost-effective method for producing complex metal structures.

You can search for more information on Snorable.

Advantages And Considerations

- Precision and Detail: Electroforming enables the creation of intricate and detailed metal structures with precise thickness control, allowing for complex designs and fine features.

- Material Selection: Various metals can be used for electroforming, including copper, nickel, gold, and silver, offering flexibility in material selection based on the desired properties and applications.

- Process Challenges: While electroforming offers numerous advantages, the process requires expertise, careful control of parameters, and attention to environmental factors to achieve consistent results and prevent issues like porosity or surface imperfections.

Conclusion

Electroforming stands as a testament to the fusion of science, technology, and craftsmanship. Its ability to create detailed and intricate metal structures with precision and versatility has made it a valuable technique across diverse industries. From creating delicate jewelry pieces to fabricating intricate microdevices, electroforming continues to push the boundaries of what’s possible in metallurgy and manufacturing, showcasing its significance in the realm of advanced production and design. As technology and innovation advance, the applications and potential of electroforming are likely to continue expanding, offering new avenues for creativity and precision manufacturing.

FAQ

What Is Electroforming In Jewelry?

Electroforming is a jewelry process where multiple layers of metals are allowed to build up, or “form” onto a surface. The artist can control where the metal will form on the jewelry piece by first painting the pattern on the item with a special, electro-conductive paint.

Is Electroform Jewelry Real Gold?

First, we need to define what electroforming is: It is simply electroplating a complex, three-dimensional shape (called a mandrel, model, or pattern). In the case of jewelry design, the mandrel is plated with a thick layer of gold that follows the shape and surface details of the mandrel.

Is Electroform Jewelry Worth Anything?

Copper electroformed jewelry can be sold for a good price. Most electroforming artists sell their jewelry between $50 and $150 a piece. Sometimes even up to $200. That is quite good, so when you make a sale you truly are happy, believe me!

What Is The Electroforming Process?

Electroforming is a metal forming process that uses electrodeposition to form, or grow, metal parts onto a model, which is known as a “mandrel.” Electrodeposition involves the electrochemical transfer of metal ions through an electrolyte to a surface from an anode.

I Have Covered All The Following Queries And Topics In The Above Article

What Is Electroforming Jewelry

What Is Electroforming Gold

What Is Electroforming Sterling Jewelry

What Is Electroforming Jewelry

What Is Electroforming Metal

What Is Electroforming Process

What Is Electroform Gold

Electroforming Vs Electroplating

Electroforming Machine

Electroforming Diagram

Electroforming Jewelry Kit

What Is Electroforming