Homemade acoustic panels can be a great solution for those looking to improve the sound quality of their home or recording studio. This type of panel is designed to absorb sound waves, reduce echo, and prevent noise from bouncing back off walls. With a few simple materials and tools, you can create your own acoustic panels that will help you achieve the desired acoustics in whatever space you choose. Furthermore, DIY acoustic panels are often much cheaper than purchasing pre-made versions. In this guide, we’ll discuss what materials and tools you need to make your own homemade acoustic panels as well as provide step-by-step instructions for constructing them.

What are Acoustic Panels

Acoustic panels are a type of soundproofing material that can be used to reduce the reverberation time of a room. Acoustic panels are made from sound-absorbing materials like fiberglass, rock wool, and other synthetic fibers, which absorb sound waves instead of reflecting them back into the room. The purpose of DIY acoustic panels is to reduce noise levels in areas such as recording studios, conference rooms, and other spaces where conversations need to be heard clearly.

Acoustic panels come in a variety of shapes and sizes and can be hung on walls or ceilings with mounting hardware. They are generally made from lightweight materials that allow for easy installation without requiring structural changes to the existing building space. The most common type is rectangular acoustic paneling with an absorptive surface on one side and a reflective surface on the other. These types of acoustic paneling are usually covered in fabric or another decorative material for aesthetics purposes.

Click here – The CPAP Machine: Revolutionary Technology That Helps Sleep Apnea Sufferers

Benefits of Homemade Acoustic Panels

If you’re a musician, sound engineer, or simply someone who appreciates great sound quality, then you know the importance of acoustic panels. Not only do these panels help to reduce echoes and reverberations in a space, but they also aid in improving sound clarity and accuracy. Unfortunately, professional acoustic panels can be expensive and out of reach for many people. Fortunately, with some creativity and resourcefulness, you can make your own homemade acoustic panels to enjoy the same benefits without breaking the bank.

The primary benefit of homemade acoustic panels is cost savings. You can create an effective acoustic panel at home with common household items like foam boards or even old blankets – all costing very little to nothing at all. Additionally, if you’re looking for more custom options that still won’t break the bank then there are some affordable materials available online such as Auralex Acoustics Foam which is designed specifically for soundproofing applications.

Materials Needed for Homemade Acoustic Panels

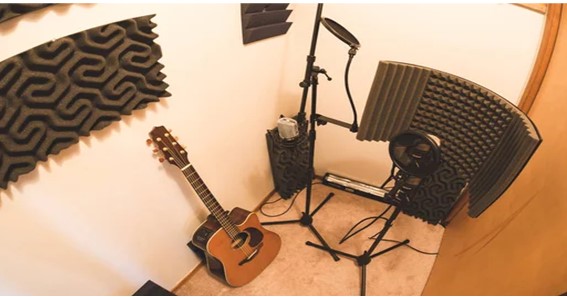

Do you want to reduce the noise levels in your home recording studio or small music venue? Homemade acoustic panels can be an effective and inexpensive solution. Acoustic panels work by absorbing sound waves and preventing them from bouncing off surfaces and echoing back into the room. With a few simple materials, you can create your own acoustic panels that will help control reverberation, sound reflections, and unwanted echoes in any space.

The first material you will need is foam. Foam is an excellent material for acoustic absorption because it absorbs sound vibrations efficiently without losing its shape or decreasing its effectiveness over time. You can find foam easily at most fabric stores or online retailers, but make sure to get a type of foam specifically designed for audio applications as it will be denser than regular types of foam. The thickness of the foam should also be around two inches thick so that it’s able to absorb more sound waves effectively.

Steps to Making Homemade Acoustic Panels

Making acoustic panels at home is an effective way to reduce sound reverberation in a room. Not only can they improve the sound of your favorite song or movie, but they are also relatively cheap and easy to make. Here are some steps you can take to make your own acoustic panels and get the most out of them.

- Gather Materials: The first step is to collect all the materials you’ll need for your acoustic panel project. You’ll want to purchase a roll of heavy-duty foam, some fabric (preferably one with noise-absorbing qualities), wood glue, scissors, staples, and a staple gun. If you’re feeling ambitious, you may also want to pick up some wood screws or nails for extra stability when mounting the panels on the wall or ceiling.

- Cut Out Foam: Using a ruler and straightedge as guides, cut out several pieces of foam that match the size dimensions you desire for your acoustic panel project (for reference purposes only). Be sure not to make them too large as this will lead to bulky frames which will be harder to mount on walls/ceilings later on in the process.

Click here – 7 Reasons Why You Need a Virtual Number for SMS

Considerations for Placement of Homemade Acoustic Panels

For those looking to improve the sound quality in their studio or home theatre, acoustic panels provide a simple and cost-effective solution. Unlike commercial acoustic panels, homemade acoustic panels can be tailored to fit any space and budget. Before investing in materials and constructing your own acoustic panel, there are several considerations you should take into account for optimal results.

- The Size of Your Room: The size of your room determines the number of panels you will need as well as their placement. Generally speaking, the larger the room is, the more acoustic panels you will need to adequately absorb sound waves bouncing off walls and other surfaces. Additionally, if your room has hard surfaces such as concrete or tile floors, then using thicker material for your homemade acoustic panel may be necessary to effectively absorb all frequencies in that space.

- The Frequency Range You Want To Reduce: Acoustic foam is designed with different levels of absorption depending on frequency range it’s targeting; low-end sounds require thicker foam while higher frequencies require thinner materials such as fiberglass insulation or rockwool. Accurately gauging which frequency range needs more absorption can help prevent overspending on foam thicknesses that won’t be used properly within a certain environment.

Conclusion

Homemade acoustic panels offer an affordable, effective solution to managing sound waves in your home. They can be made from a variety of materials, such as foam, fabric, and wood. With the right supplies and some know-how, anyone can craft their own acoustic panels and enjoy the many benefits they bring.